Discover all the key components of a complete IBC tank, from metal cage mesh and base structure to plastic inner tank, valve, lid, and protective accessories.

An Intermediate Bulk Container (IBC) is not a single product, but a carefully engineered system composed of multiple structural and functional components.

Each part plays a critical role in strength, safety, durability, and transport performance.

Below is a detailed, step-by-step explanation of all main components that form a complete IBC tank, following the actual manufacturing and assembly process used in modern IBC production lines.

The production of an IBC cage starts with a welded metal wire mesh panel, manufactured on an automatic cage welding line.

Provides external mechanical protection

Ensures stacking strength

Maintains container shape during transport and storage

Precisely welded steel wires

Uniform mesh spacing

High welding consistency to avoid weak points

This metal mesh panel is the structural backbone of the IBC cage.

Once the mesh panel is completed, it is automatically bent into a square cage shape.

The flat mesh is bent at precise angles

The head and tail ends are aligned and connected

Dimensional accuracy is strictly controlled

Accurate bending ensures:

Perfect fit with the plastic inner tank

Stable load distribution

Uniform appearance across all IBC units

After cage forming, the lower part of the cage goes through a punching and flattening process using a punching & flattening machine.

Remove specific bottom sections of the wire

Create flat, connection-ready surfaces

Prepare the cage for base assembly

This process allows the cage to be securely connected to:

Steel base pallets

Plastic base pallets

Wooden pallets (in some regions)

Without this step, stable base fixation would not be possible.

The base (pallet) is a critical load-bearing component of the IBC tank.

Steel pallet: Highest strength and durability

Plastic pallet: Lightweight and corrosion-resistant

Wooden pallet: Cost-effective for specific markets

Supports full liquid load (up to 1000 liters)

Enables forklift handling

Ensures safe stacking and transport

The formed metal cage is mechanically fixed to the base using bolts and screws.

Strong and reliable connection

Easy maintenance or replacement

Compatible with different base types

This step finalizes the rigid outer structure of the IBC.

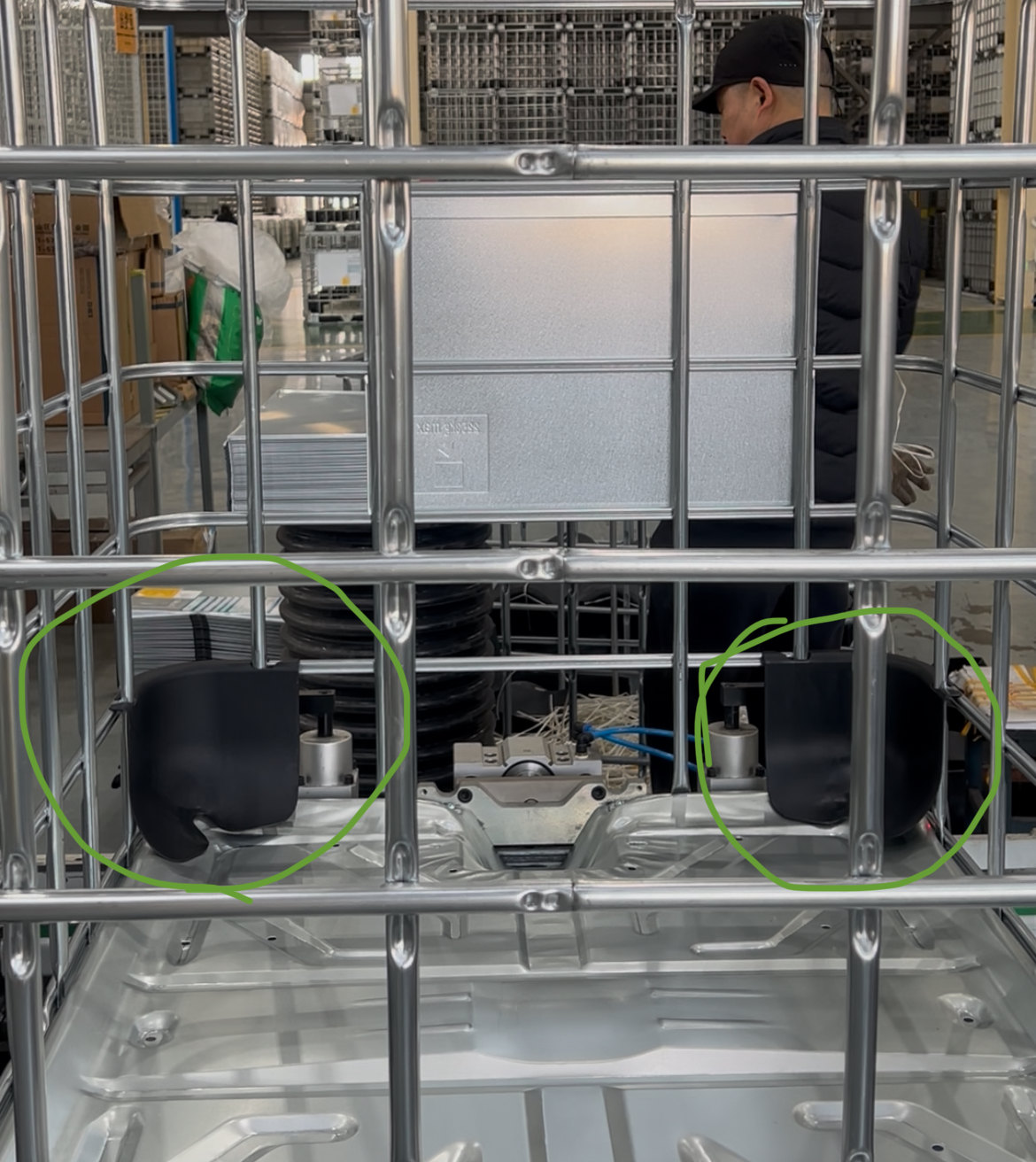

To prevent direct contact between the plastic tank and metal cage, plastic corner protectors are installed.

Reduces friction during transport

Prevents abrasion and wear

Extends the service life of the inner tank

Improves overall safety

These small components play a big role in long-term durability.

A complete IBC tank is finished with essential functional components:

Installed at the bottom of the inner tank

Controls liquid discharge

Available in different materials and standards

Seals the filling opening

Prevents contamination and leakage

Improves liquid stability

Reduces movement during transport

Enhances safety for liquid handling

A fully assembled IBC tank includes:

Welded metal wire mesh panel

Bent and formed metal cage

Punching & flattening preparation

Steel / plastic / wooden base pallet

Bolted cage-to-base connection

HDPE plastic inner tank

Corner protectors

Valve, lid, and baffle

Each component must be precisely manufactured and perfectly integrated to ensure product quality, safety, and compliance with international standards.

Ningbo Xinzhou Welding Equipment Co., Ltd. provides complete IBC production line solutions, including:

IBC cage welding production lines

Cage bending, punching, and flattening systems

Steel pallet welding lines

IBC blow molding machines

Raw material supply (wire, tubes, pallets)

Valves, lids, corner protectors, and accessories

Turnkey IBC factory solutions

From individual machines to full production lines, we help customers build stable, efficient, and scalable IBC manufacturing systems.